Tag: Electrician School

4 Common Residential Electrical Flaws Examined for Those Who Want to Become An Electrician

December 02, 2020 Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

While some of these problems may appear to have harmless symptoms, many of them left unattended have the potential to cause tragic house fires or electrocutions. With that in mind, here are a few of the most common—and potentially hazardous—electrical flaws pros should look out for in people’s homes.

1. Plugs Fitting Loosely in Receptacles

Many homeowners may have noticed an outlet or two in the home where the prongs of electrical devices don’t seem to fit as firmly as they should. This problem is usually caused by the contacts of the outlet receptacle becoming worn over time, causing the plug to sit loosely in the outlet, with the metal prongs of the plug often partially exposed.

Electricity will usually still flow in this circumstance, posing a high fire risk due to loose contacts causing electrical arcing. Any flammable object near the compromised outlet is at risk of igniting, such as bed skirts, curtains, or even an accumulation of dust. While the fire risk is high in this circumstance, the repair work is simple, requiring a quick, low-cost receptacle replacement.

2. An Absence of GFCIs

Ground fault circuit interrupters (GFCIs) are built-in outlet fixtures designed to prevent hazardous electrical shocks. A person with electrician training should be aware of this design, which is usually found in wet regions of the home where electrocution is more likely, such as bathrooms, the kitchen sink area, and outdoor connections. On an inspection, the electrician should look out for GFCIs in these areas of the home, and recommend replacements to older outlet coverings for optimized safety.

3. Overlamping

Even students of electrician school may have at one time or another made the common homeowner error of using a lightbulb with higher wattage than a light fixture is designed to accommodate. It may seem like a small problem, but the mistake rates as a fire risk due to the extreme overheating that will eventually scorch the light socket.

Not only is the socket at risk of melting, but the heat can also burn its way through the fixture’s wires, causing the arcing phenomenon that’s usually at the root of so many electrical fires in the home. Even if the homeowner is lucky enough to avoid a fire from a longer period of overlamping, the light fixture will usually be permanently damaged. To prevent all risk, homeowners should be advised to always ensure they’re using a bulb with the recommended level of wattage limits labeled on the light fixture.

4. Ungrounded Connections

Students of electrician school will need to understand the concept of grounding, which is a safety feature design added to electrical appliances, devices, and outlets to safely discharge an excess of electricity in the event of a wiring defect. If currents escape from the safety of the wiring unit in such defects, connections without a grounding system leave those loose currents at risk of flowing through nearby objects instead. This poses a damage risk to the device in question, and an electrocution risk to the person using it. As a standard safety measure, electricians should highly advise any homeowner with insufficient grounding connections and wiring to invest in an updated installation.

Are you interested in taking professional training to become an electrician?

Contact North American Trade Schools today for more information on its specialized program!

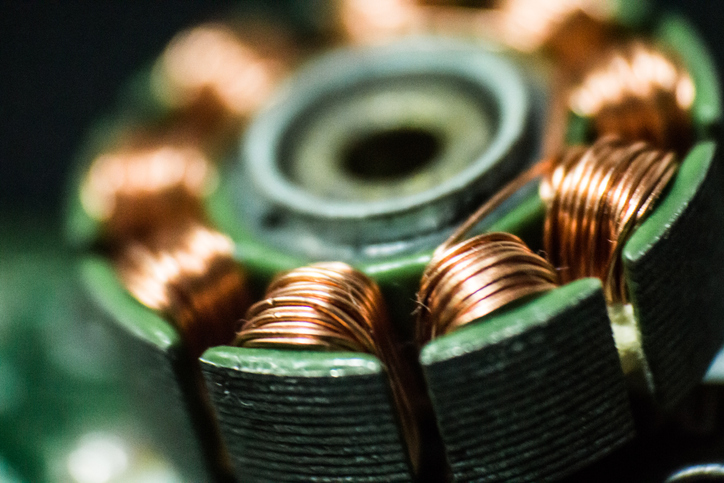

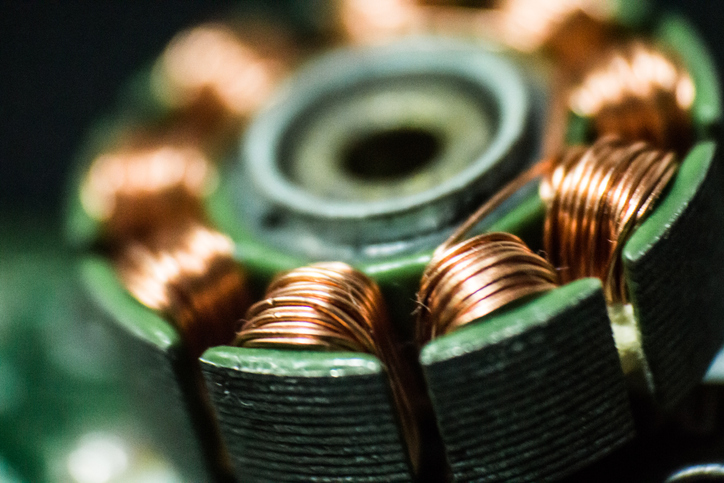

4 Things for Electrician School Students to Know About Electric Motors

October 15, 2020

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

Electrical Power Systems in Buildings Explained for Those in Electrician School

August 25, 2020

Have you ever wondered how electricity flows into buildings? An electrical power system helps make this into a reality. With electrical power systems and their parts and conductors, they can vary based on how big or small the building is. The processes used to deliver electricity into those buildings can also differ based on the size and nature of the building. Electrical power is delivered and converted to any load in the building using the electricity. The power being distributed within the buildings can differ depending on both the size of the building using it and the system itself.

Understanding how electricity travels towards outlets in rooms in a building is important to know for your electrician career, as well as the necessary procedures for it to travel efficiently within the building, regardless of size. Here’s what an aspiring electrician should know about electrical power systems in buildings.

Important Facts for Electrician School Students to Know

For any electrical power system, electricity is delivered via conductors, which brings power between two different areas of the building. Usually in electrical cable form, conductors deliver electricity to a load device from a generator, and are often made of copper. It’s typically at extremely high voltages that power is transmitted from the plant to buildings, as this is what is most effective. However, smaller buildings have electricity delivered through a meter with lower voltage numbers via a transformer. A switchgear will then be used to not only be an on-off switch for the circuit (with current flow being either automatic or manual), but also to protect equipment from the power supply. Lastly, a load device such as a heating unit is used to turn electricity into energy types like light or heat.

Larger-Sized Buildings: Bigger Spaces Need Bigger Systems

A big building needs an equally big load of electricity. Electrical equipment must also be proportionately sized for the power it would carry, and a transformer would be used to lower the high voltages coming through it. A switchgear—or multiple ones, if the building needs more than one transformer—then delivers electricity to various parts of the building, via either a bus or feeder. Students in electrician school probably already figure this is the case, but large-scale buildings need more power, and electrical systems for these types of buildings are used to study factors like load flow to ensure the conductors and equipment are sized accordingly. With taller buildings such as high-rise apartment complexes, high-voltage lines can be brought into the building in order to place different transformers in rooms on different floors.

Smaller-Sized Buildings and Residences: A Simpler Process for Power

Those in electrician training may already know that smaller buildings and homes do not have a very complex system for distributing electricity. In these instances, either a utility pole or a pad will have the transformer attached to it–reducing the voltage before power goes to the meter. About 13,800 volts from the utility is significantly reduced, with power later going from the meter into the building. It then travels to a panel board with a series of breakers. Various circuit-based components in a home, such as lights or electrical outlets, will have this power flowing toward it. Residential homes often use low voltages of electricity, ranging between 110 and 260 volts. Smaller buildings such as low-rises tend to use step-down transformers, which reduce voltage to various levels depending on the size of the device using it.

Do you want to start your maintenance electrician training?

Contact North American Trade Schools to learn more!

3 Environments You Might Be Working in After Electrician School

September 09, 2019

If you’re about to begin a career as an electrician, there are numerous possibilities for where you might work. You could ply your trade in homes, office buildings, construction sites, or industrial factories. Whether you want to work indoors or outdoors, travelling or just at one site, there’s an electrician job for you.

Wherever you end up going, your job remains to ensure electricity safely goes straight from the source to those who need it the most. Here are three places you might find yourself working in after completing your program to become an electrician.

1. You Could Find Yourself Working in People’s Homes After Electrician School

Residential electricians work on wiring and lighting in people’s homes and apartment buildings, among other living spaces. In this career, you could find yourself going to different homes, carrying out the necessary tasks to make sure residential buildings and units have electricity in place, and installing it both indoors and outdoors as necessary.

Your tasks could include determining where equipment and fixtures will be located in the home, working on security and air conditioning systems, and ensuring electricity can travel from the source to the home’s circuit breaker. Whether you’re working on an existing home, or one that’s still being constructed or undergoing renovations, you’ll be able to work on electrical wiring and fuses to keep tenants and families happy and their homes running smoothly.

2. You Could Work in Any Environment Specializing in Maintenance

If you you’re the type of person who likes fixing things that are broken or not working properly, being a maintenance electrician may be the route for you. Travelling and commuting between different worksites is common for people in this job, so you could find yourself working in various environments. If you want a job where your workplace will change every day, this job could be a great fit.

As a maintenance electrician, you could be performing tasks like troubleshooting using testing devices, performing preventative maintenance, rewiring connections or electrical equipment in homes or businesses, or working on equipment in factories or manufacturing units. Regardless of where exactly your career after studying to become an electrician takes you, your problem-solving skills and ability to carry out the necessary maintenance procedures will serve you well if you want to become a maintenance electrician.

3. You Could Work in Office Buildings (or Outside Them) as a Commercial Electrician

Businesses need light and electricity during the work day and sometimes even at night, so they need commercial electricians to help set up their electrical systems and keep them running. In this environment, you could be installing lighting, wiring, and/or control and security systems, while adhering to all safety requirements.

Alternatively, you could work as an electrician on a construction site where a new office building is being built, or at a factory as an industrial electrician where you may work on hydraulic and other machinery. Regardless, whether you work in a small corner of an office building or a wide-open construction space, your career after electrician school can lead to you working for a number of successful businesses.

Want to get your electrician diploma?

Contact North American Trade Schools to learn more about our programs!