Tag: electrician training

3 Challenges to Expect After Electrician College, and How to Tackle Them

December 22, 2020

The job of an electrician isn’t easy. Electrical problems are a common occurrence in all kinds of structural installations, requiring anything from a simple fix to a complex solution. If not addressed, electrical issues can lead to electrical shocks, fires, or other unsafe conditions. Electricians are vital when it comes to solving electrical problems as they occur, and knowing how to fix common problems safely is essential to a job well done. Most electrical issues are caused by low-quality parts, a lack of regular maintenance, or failure to comply with codes and regulations. Fortunately, all of these problems can be fixed by a qualified electrician. If you want to become an electrician, then you’ll want to be aware of these three common challenges that electricians often face on the job, and how to handle them.

Those With Electrician Training Should Look Out for Overcrowded Electric Control Panels

Disregarding electrical codes and regulations when putting electrical systems and circuits in place can seriously increase the chances of encountering an electrical problem down the road. Once called in, a qualified electrician should be able to identify and address the problem. One common reason an electrician will be called to the scene is when a breaker or fuse is regularly tripping or blowing. A professional with electrician training will be able to identify the cause of this. Often, the cause can be an overcrowded electric control panel. Too many circuits, breakers, and wires on one control panel can cause overloading, leading to the overheating of components attached to the panel and issues with the fuse and breaker. If left unattended, overloading can cause fires. Electricians can solve this problem by switching to a panel of a larger size, and ensuring that the total load is not above the rating of the breaker or fuse. By being familiar with electrical codes and regulations, this problem can be mitigated.

Haphazard Wiring Methods

If you want to become a construction electrician, one of the main difficulties you’ll encounter throughout your career is incorrect wiring practices. Incorrect wiring practices can be identified by checking power outlets. If they are warm or emitting a burning smell, this is often a sign of faulty wiring. If the wires’ conductors are the wrong size or incorrect connections are used, this can leave wires exposed, causing the insulation to deteriorate and the wires to melt. When exposed wires come in contact with flammable or combustible material, outlets can become warm or emit a burning smell. Electricians can often fix this problem by replacing the conductor with one that is the right size for the wires.

Unsecured Connections

Loose connections refer to an electrical connection that isn’t tight enough, which can cause a buildup of heat and can increase the risk of an electrical fire. A common sign of a loose connection is the frequent flickering or burning out of light bulbs, and can even manifest in a smoke detector going off when it shouldn’t. If the frequency of this occurring is unusual, electricians may suspect that a loose connection is causing the issue rather than the light bulb itself. Loose connections can cause lasting detriment to electrical appliances and can even cause electrical fires. Electricians can solve this issue by cleaning the loose conductors and tightening the connection in concern.

These are just some of the many problems electricians may face during a day’s work, and it’s important to be knowledgeable about the potential issues that can occur on the job in order to safely and effectively solve the problem.

Are you thinking about attending electrician college?

The North American Trade School has the program for you. Start exploring today!

4 Common Residential Electrical Flaws Examined for Those Who Want to Become An Electrician

December 02, 2020 Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

Electricians called into homes to work on a specific problem have often reported discovering additional electrical issues, some of them potentially hazardous. Many electrical issues in the home are caused by work done by unqualified people, or by homeowners trying to save a few bucks with DIY home reno jobs. Electrical defects are also frequently found in older homes, where outdated fuse boxes, outlets, and wiring are often ill-equipped to supply the power demands of the many modern electrical devices used in the average household of today.

While some of these problems may appear to have harmless symptoms, many of them left unattended have the potential to cause tragic house fires or electrocutions. With that in mind, here are a few of the most common—and potentially hazardous—electrical flaws pros should look out for in people’s homes.

1. Plugs Fitting Loosely in Receptacles

Many homeowners may have noticed an outlet or two in the home where the prongs of electrical devices don’t seem to fit as firmly as they should. This problem is usually caused by the contacts of the outlet receptacle becoming worn over time, causing the plug to sit loosely in the outlet, with the metal prongs of the plug often partially exposed.

Electricity will usually still flow in this circumstance, posing a high fire risk due to loose contacts causing electrical arcing. Any flammable object near the compromised outlet is at risk of igniting, such as bed skirts, curtains, or even an accumulation of dust. While the fire risk is high in this circumstance, the repair work is simple, requiring a quick, low-cost receptacle replacement.

2. An Absence of GFCIs

Ground fault circuit interrupters (GFCIs) are built-in outlet fixtures designed to prevent hazardous electrical shocks. A person with electrician training should be aware of this design, which is usually found in wet regions of the home where electrocution is more likely, such as bathrooms, the kitchen sink area, and outdoor connections. On an inspection, the electrician should look out for GFCIs in these areas of the home, and recommend replacements to older outlet coverings for optimized safety.

3. Overlamping

Even students of electrician school may have at one time or another made the common homeowner error of using a lightbulb with higher wattage than a light fixture is designed to accommodate. It may seem like a small problem, but the mistake rates as a fire risk due to the extreme overheating that will eventually scorch the light socket.

Not only is the socket at risk of melting, but the heat can also burn its way through the fixture’s wires, causing the arcing phenomenon that’s usually at the root of so many electrical fires in the home. Even if the homeowner is lucky enough to avoid a fire from a longer period of overlamping, the light fixture will usually be permanently damaged. To prevent all risk, homeowners should be advised to always ensure they’re using a bulb with the recommended level of wattage limits labeled on the light fixture.

4. Ungrounded Connections

Students of electrician school will need to understand the concept of grounding, which is a safety feature design added to electrical appliances, devices, and outlets to safely discharge an excess of electricity in the event of a wiring defect. If currents escape from the safety of the wiring unit in such defects, connections without a grounding system leave those loose currents at risk of flowing through nearby objects instead. This poses a damage risk to the device in question, and an electrocution risk to the person using it. As a standard safety measure, electricians should highly advise any homeowner with insufficient grounding connections and wiring to invest in an updated installation.

Are you interested in taking professional training to become an electrician?

Contact North American Trade Schools today for more information on its specialized program!

4 Things for Electrician School Students to Know About Electric Motors

October 15, 2020

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

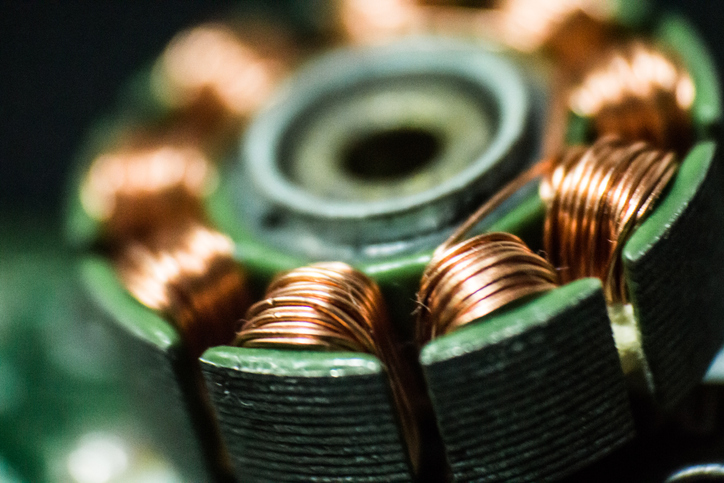

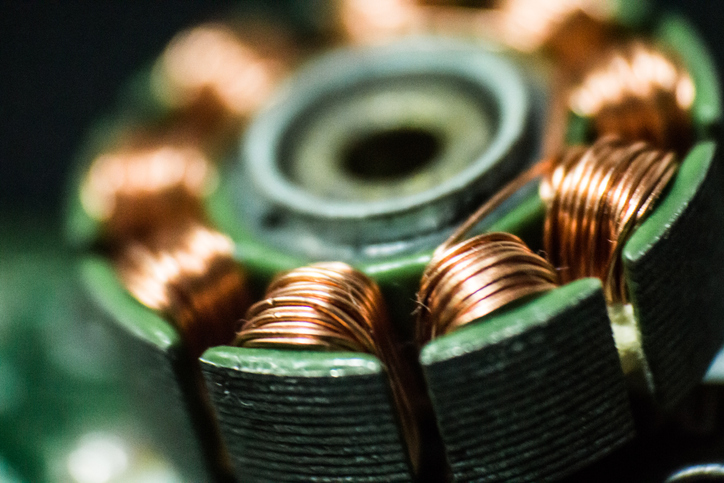

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

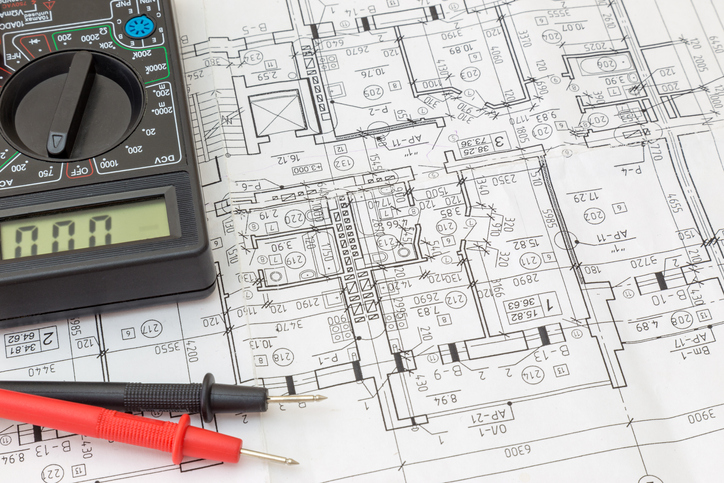

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

They’re found in appliances and toys throughout your house: remote control cars, electric can openers, computers, washing machines, electric mowers, electric toothbrushes, and much more. In fact, the electric motor might just be one of the most useful electrical inventions since Benjamin Franklin discovered electricity!

Most electric motors have a four-pole permanent magnet motor with double insulation design that runs at 120 volts. They work by adding electricity at one end, which sends a jolt to rotate the metal axle at the other end to power whichever machine the motor lives in.

What else should you know about these incredibly useful and common motors? Here are four things to keep in mind about their design and functioning.

1. They Work Using Electromagnetism

Those attending electrician school will learn electrical motor theory. When power is added, what really happens is that current flows through the motor’s coil to generate a magnetic force. One side of this force will flow in the direction the magnetic field is heading in, while a force generated on the other side of the housing will begin flowing the other way. Rotation on the armature thus happens, as an up-and-down action is created.

Most small household appliances like blenders and coffee grinders are run by a universal electric motor. This motor uses an electromagnet to take its energy from the DC or AC power feed, as the motor can be either AC or DC-powered.

2. Dynamic Braking Is Used for Safety

Most electric motors handle safety with the addition of a dynamic braking feature, also known as rheostatic braking. Located inside the circuitry of the motor, handle switch, and wire harness, the dynamic brake is activated upon the handle switch’s release. After the handle switch moves into the off position, the motor is brought to a complete halt.

There are also two other types of electric braking commonly found in the DC motor. Plugging—also called reverse current braking—gives greater braking torque than dynamic braking, and is more commonly used in larger machines such as printing presses and elevators. Regenerative braking is used when there is heavy inertia on the load on the motor, as one would find with an electric train.

3. Improper Maintenance Is the Leading Cause of Malfunction

Many electric motors will last longer if given the right level of care. Electric mowers and HVAC units are good examples of things needing regular maintenance, due to their exposure to grass, dirt, dust, and other contaminating elements.

At least once a year, an electric motor that can be contaminated in this way should be inspected and have all of its parts cleaned. This helps to avoid incidences of overheating by removing anything that may be clogging the filter and air cooling system of the machine.

4. Specialized Electrician Training Is Helpful for Attending to Repairs

To diagnose a problem with an electric motor, a technician with electrician training should start by using a digital multimeter to assess the components. Once a problem has been identified, the motor must often be disassembled to proceed with repairs. From there, the parts can be assessed for damage, corrosion, rust, or other contaminants. Brushes will often need to be replaced, along with any damaged parts, but rust and corrosion can usually be cleaned off with a wire brush.

Electric motors are an essential part of modern life, used to power all kinds of machinery in and out of the household. Most of the designs on these kinds of motors are built to last, and will tend to have a good lifespan as long as they are well-maintained. When problems occur, people rely on the specialist knowledge that those trained on electric motor theory can provide.

Interested in learning more about electric motors by receiving professional training at an electrician college?

Contact North American Trade Schools today for more information on our Construction & Maintenance Electrician Pre-Apprenticeship diploma program!

5 Facts About Residential Wiring for Those Interested in Electrical Training

September 29, 2020

If you’re considering becoming an electrician, you might be surprised by the variety of standards and regulations set in place for wiring systems in residences such as homes and cottages. Homes contain a variety of appliances and safety features which require electrical wiring. Hydro One, Ontario’s electricity provider, has a number of specifications in place for how they are to be installed within the home.

Here are five things to consider with regards to residential wiring.

Wiring Sizes May Be Different for Residences

For residences, common wire sizes may be different from other types of buildings. The American Wire Gauge Number (AWG) serves as the standard measurement of a wire’s diameter. Residences typically use four kinds of AWG wire sizes, with different amp circuit numbers for each: 8 (40 amp circuits), 10 (30), 12 (20), and 14 (15). The No. 8 AWG is often used for loads like electric ranges. No. 10 is used for loads needing electricity, such as dryers and electric water heaters. No. 12 serves loads like kitchen counter receptacles (e.g. appliances like microwaves). And No. 14 works best with loads such as lights (eg. lamps), switches, smaller appliances, and receptacles. Electrical box sizes may also vary, but this depends on several factors. These include the mounting of switches or receptacles, how many wire conductors are present, how many are in use, and the conductors’ sizes.

Many Different Appliances Require Electrical Installation in a Home

The home has a variety of appliances which have different electrical installation needs. The oven, refrigerator, dishwasher, counter spaces, built-in microwave ovens (and possibly more) all require consideration when planning for residential wiring. These appliances typically require their own, separate receptacle, from an entirely different circuit. As those with electrician training may know, any receptacle with 15 to 20 amp circuits must not only be marked, but tamper-resistant. This is because inserting any conductive object that is not a plug into the receptacle can cause electric shock. However, Hydro regulations state that, if a stationary appliance’s receptacle is a minimum of two metres above ground and/or out of reach, tamper resistance is not necessary. Prior to installation, be sure to mark on your floor plan where these appliances—and their corresponding receptacles—are located.

Different Rooms Within the Home Require Different Wiring Configurations

If you’ve completed maintenance electrician training, you will need to follow many requirements when working on residential homes. Hydro One has a set of requirements for each room in the house to ensure safe living conditions for residents. For one, each room must be equipped with a light controlled by a light switch. Two lights controlled by a three-way wall switch—one for the bottom and the top each—is required for any stairway containing a minimum of four stairs. Keep in mind that, on any two-wire branch circuit, 12 outlets are allowed at maximum. This includes receptacles and lights. Range receptacles must also be installed in the home with their receptacles marked on the floor plan.

Those With Electrician Training Should Plan to Install Smoke Alarms

Smoke alarms are an important and necessary safety feature for homes. They are required to be installed on each of the home’s floors, and a battery backup should also be present. Additionally, there should be one in each bedroom and an additional alarm in hallways attached to them. These smoke alarms must all be interconnected and should operate at 120 volts. Either a branch circuit with a receptacle/lightning combination or an unswitched lighting branch circuit can be used for these alarms.

Service Size May Depend on the Requirements of the Home

Typically, homes should have a distribution panel containing 24 circuits, and a service size of at least 100 amps. When calculating the service size, take into account the kilowatt demand. There are multiple factors which help to determine this, such as electric heating, the area of the floor, and appliances, among other loads that may be present. Although the service size should be larger if a home requires greater amounts of heating, most homes with a minimum 100-amp service size should be able to maintain both their typical electrical loads and electrical heating of up to 10 kW.

Do you want to become a construction electrician?

Check out North American Trade Schools’ programs today!

Electrical Power Systems in Buildings Explained for Those in Electrician School

August 25, 2020

Have you ever wondered how electricity flows into buildings? An electrical power system helps make this into a reality. With electrical power systems and their parts and conductors, they can vary based on how big or small the building is. The processes used to deliver electricity into those buildings can also differ based on the size and nature of the building. Electrical power is delivered and converted to any load in the building using the electricity. The power being distributed within the buildings can differ depending on both the size of the building using it and the system itself.

Understanding how electricity travels towards outlets in rooms in a building is important to know for your electrician career, as well as the necessary procedures for it to travel efficiently within the building, regardless of size. Here’s what an aspiring electrician should know about electrical power systems in buildings.

Important Facts for Electrician School Students to Know

For any electrical power system, electricity is delivered via conductors, which brings power between two different areas of the building. Usually in electrical cable form, conductors deliver electricity to a load device from a generator, and are often made of copper. It’s typically at extremely high voltages that power is transmitted from the plant to buildings, as this is what is most effective. However, smaller buildings have electricity delivered through a meter with lower voltage numbers via a transformer. A switchgear will then be used to not only be an on-off switch for the circuit (with current flow being either automatic or manual), but also to protect equipment from the power supply. Lastly, a load device such as a heating unit is used to turn electricity into energy types like light or heat.

Larger-Sized Buildings: Bigger Spaces Need Bigger Systems

A big building needs an equally big load of electricity. Electrical equipment must also be proportionately sized for the power it would carry, and a transformer would be used to lower the high voltages coming through it. A switchgear—or multiple ones, if the building needs more than one transformer—then delivers electricity to various parts of the building, via either a bus or feeder. Students in electrician school probably already figure this is the case, but large-scale buildings need more power, and electrical systems for these types of buildings are used to study factors like load flow to ensure the conductors and equipment are sized accordingly. With taller buildings such as high-rise apartment complexes, high-voltage lines can be brought into the building in order to place different transformers in rooms on different floors.

Smaller-Sized Buildings and Residences: A Simpler Process for Power

Those in electrician training may already know that smaller buildings and homes do not have a very complex system for distributing electricity. In these instances, either a utility pole or a pad will have the transformer attached to it–reducing the voltage before power goes to the meter. About 13,800 volts from the utility is significantly reduced, with power later going from the meter into the building. It then travels to a panel board with a series of breakers. Various circuit-based components in a home, such as lights or electrical outlets, will have this power flowing toward it. Residential homes often use low voltages of electricity, ranging between 110 and 260 volts. Smaller buildings such as low-rises tend to use step-down transformers, which reduce voltage to various levels depending on the size of the device using it.

Do you want to start your maintenance electrician training?

Contact North American Trade Schools to learn more!

Exterior Wall Components for Electrician Training and Beyond

December 13, 2019

When you study construction maintenance for electricians, you will have the opportunity to apply what you learn in the classroom to hands-on training. This will include working on skill sets for commercial, industrial and residential electricity, analyzing and preparing machine controls, and building an exterior wall, among other things.

Exterior building walls, on first glance, may just appear to be what you see from the outside. When you look at a building you may see materials like brick, cement, siding, or shingles. However, the construction of an exterior wall that is fit for its environment is a complex process that requires a lot of attention to detail and design. Here are a few important points about exterior wall components.

A Brief Introduction to Components for Electrician Training

During your electrician training it will become clear that understanding a building layout and how walls are constructed is important for maintaining electrical systems. The exterior wall assembly in particular helps protect the interior of a building from outside elements. This not only refers to providing shelter for people, but also keeping systems within the building running properly.

Here is a quick introduction to the components of exterior wall assembly:

- Exterior cladding: this layer is chosen based on environmental conditions as well as aesthetics. It is the first, but not most important, defence against weather.

- Air barrier, also known as air paper or house wrap: this is a weather resistant layer that allows moisture to escape.

- Vapour control layer: moisture can build up in the exterior wall assembly without this component so it is typically required by building codes and regulations.

- Insulation: this supports interior temperature control.

- Structural element: this is the load bearing component (or components) that distributes weight and pressure to the structural frame of a building.

Interface Conditions

After you are introduced to the functions of each component of an exterior wall assembly it is important to understand how each component affects the whole. Essentially, the assembly must be able to control and mitigate moisture and protect the interior, including its electrical systems. The ways in which the components of the wall assembly are separated, joined and installed, are referred to as the interface conditions. For example, elements like flashing and end dams prevent excess rain from entering the dry zone of the assembly and may be necessary around windows, or where the wall meets the roof.

Examples of Common Materials

There are many standard materials for exterior wall assemblies that you might be familiar with even before you start maintenance electrician training. For example, Tyvek and Typar are two of the most common polyethylene air barriers. They let water vapour out, but eliminate exterior moisture, thus protecting wiring that may otherwise be vulnerable to moisture. Like tarpaper, another common air barrier, they can be damaged by UV rays.

For the exterior cladding some of the most common materials are cedar shingles, vinyl, cement board, stucco, brick, and a few others. Vinyl or steel siding can be applied directly to air paper. However, if you are using brick or stucco, the interface conditions dictate that a layer of rain screen siding may be required. At the very inside, the most common material is drywall. Overall, your expertise on each of these elements will be required as you work with building plans.

Want to become a maintenance electrician?

Find out how from the North American Trade Schools!

Infographic: 4 Awesome Benefits of Trades Careers

November 20, 2019

Are you thinking about a new career? Whether you’re just out of school or you’re thinking of switching paths, you may want to consider a career in the trades.

Canada is currently facing a shortage of skilled trades people. Despite offering an opportunity to enjoy a high standard of living, trades careers aren’t attracting enough new professionals to meet demand. This is mainly due to outdated stereotypes about “blue collar” jobs, such as them being low-paid or unsatisfying. But forget what you think you know about the trades! Surveys of people in the construction trades, for example, finds that they are happier in their careers than other Canadians.

And pursuing a career in the trades doesn’t mean you have to give up a great pay cheque for the sake of your passion. Trades people also earn impressively high salaries. After finishing electrician training, for example, you could eventually make over $63,000, which is the average salary for electricians in Canada.

Still not convinced that a career in the trades is a great idea? Check out this infographic about 4 awesome benefits of a trades career.

4 Awesome Benefits of Trades Careers

1. Trades Careers Are Hands-On

Not too keen about sitting behind a computer all day?

Trades careers allow you to work with your hands every day

Build things you can be proud of

Tackle new and exciting challenges

Trades careers involve working in a variety of interesting settings

2. Trades Workers Are In Demand

Canada is facing a skilled labour shortage

The construction industry alone will have 44,100 unfilled job vacancies by 2028

Unfilled industrial maintenance jobs are expected to be almost as high

In Ontario, 91,100 construction workers will retire by 2028

Only 77,800 new entrants will be available to replace them

If you want a job that is in extremely high demand, join the trades!

3. Trades Careers Pay Well

Think a career in the trades doesn’t pay well? Think again!

A shortage of trades workers has fueled impressive wage growth

Check out these average Canadian salaries for in-demand trades:

- Electrician: $63,236

- Plumber: $63,345

- HVAC Mechanic: $58,500

- Roofer: $56,550

- Carpenter: $52,296

- Welding: $50,700

In the trades, experience counts:

Experienced trades workers on average make up to $91,163 per year

4. Earn While You Learn

Don’t want to wait through 4 years of schooling before making money?

Pre-apprenticeship programs take less time to complete!

Once you become a trades apprentice, you’ll earn while you learn

Apprentices work under the supervision of a certified tradesperson

There are so many reasons to pursue a career in the trades!

Discover which option would best suit your interests.

Sources:

https://www.ontario.ca/page/start-apprenticeship

What Electrician Diploma Students Should Know About Reading Layouts

October 08, 2019

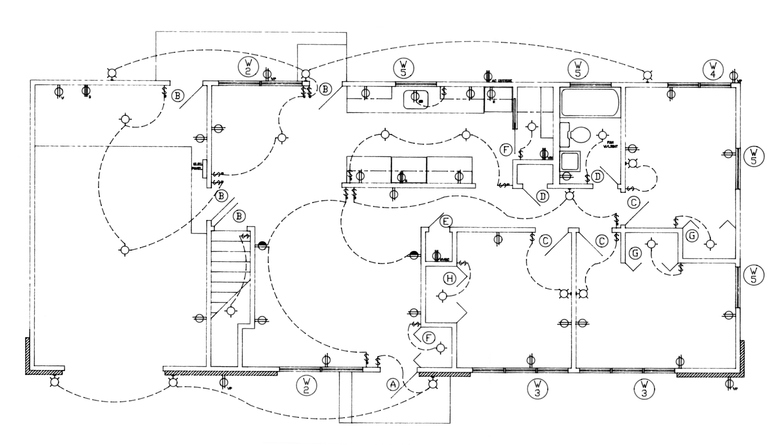

As an electrician (particularly a construction electrician), it’s important to be able to understand how to read electrical blueprints or layouts. With these layouts, you will have a better understanding of how electrical systems are to be built, and where all the various parts (eg. light fixtures, switches, wires) need to go. That said, they can be a bit complicated to look through at first. Luckily, it’s easier to get the hang of than you might think.

Regardless of all the symbols and more specialized aspects you may encounter while reading them, there are ways you can effectively interpret an electrical plan without too much trouble. Here’s what you should know about reading layouts if you’re studying to become an electrician.

Read What’s in the Architectural Layout Before the Electrical One

When you look at the floorplan for the building’s architectural layout first, you’ll get a good sense of how much space you have to work with, where things are, and where electrical parts should logically go. Not only that, but you’ll have information about the layout that isn’t necessarily in the electrical portion of the plan. This can help you identify potential conflicts between the architectural and electrical plans that you may not have noticed by only looking at the electrical plan. Either way, you’re going to need to understand what sort of parameters and space you have to work with, since you’ll have to work within them to make sure all the wires are in the right place and able to deliver power throughout the building in ways that are safe for everyone and compliant with bylaws and regulations.

Familiarize Yourself With the Wiring Diagrams and Symbol Legend Before Getting Started

In many electrical layouts, there will be symbols representing various parts, and it’s important to study the symbol legend before you start working. Once you understand the symbols legend, you’ll be able to work faster and more efficiently. The legend will help you understand what the symbols are, what they mean, and where various components need to be. The plans for the project’s electrical components will also likely show diagrams of the paths the wires will take between the different pieces of equipment—important to keep in mind since you will be learning about residential wiring in your maintenance electrician training. This will show you the breakers running each wire, as well as which items within the house (eg. lights) are grouped or phased together onto one breaker.

Your Electrician Training Will Help You to Read Blueprints

All instructions of the electrical layout have to be followed exactly as written—or drawn—and sometimes the information presented can be overwhelming and will require specialized knowledge on electrical components. For example, you’ll need to understand how power across lines will be distributed, as well as the circuit’s flow and critical points where separate wires connect. It sounds like a lot to take in, but it is important information to remember so that the job is done effectively and so that fire, sparks or other hazards can be avoided. Fortunately, in electrician training you will learn how to read blueprints and building layouts, as well as the fundamental principles of electricity. At the end of the day, no part of the layout can be misinterpreted or ignored, and learning about plans and layouts will help you become a better electrician.

Want to get your electrician diploma?

Contact North American Trade Schools to find out more!