Tag: hvac school

Sustainability is leading the conversation in most industries today. As with the majority of sectors in the construction and maintenance industry, the Heating, Ventilation, and Air Conditioning (HVAC) market is under pressure to go greener. Sustainable HVAC systems are an important innovation for both the industry and our planet. Homeowners and technical workers can benefit from new technologies that reduce the environmental impact of HVAC systems while maintaining their design integrity.

Students training for a career within the HVAC industry will study the installation and maintenance of different HVAC systems in residential and commercial environments. Gas codes and regulations are other important features of HVAC training. To get to grips with the evolving trends of the industry, read on for an overview of the benefits and concepts behind sustainable solutions in HVAC design.

The Benefits of Sustainable HVAC Systems

The drive to reduce energy consumption, greenhouse gases, and the use of fossil fuels are top concerns when it comes to sustainable design initiatives. Delivering hot water and heating to buildings produces a significant greenhouse gas footprint. Sustainable HVAC systems offer a solution to the environmental expense of traditional heating and cooling methods. HVAC systems such as heat pumps work by transferring heat between indoor and outdoor spaces to regulate the temperature of the building. In that sense, they are sustainable alternatives to boilers or furnaces that rely on fossil fuels.

Students in HVAC school might be interested to know that sustainable HVAC systems save both energy and costs in the long run. Up to 30 percent of the energy generated for use in commercial buildings is wasted. On average, HVAC systems last up to 15 years–a long time to endure high energy expenses and greenhouse gas emissions. Both workers and homeowners can benefit from the reduced cost of climate control over the building’s life cycle. It’s important for construction and maintenance technicians to know which sustainable technologies provide the best return over time.

Sustainable HVAC Solutions

There are numerous ways to achieve sustainability in HVAC systems. Thermal air conditioning is a great way to conserve energy without sacrificing power and comfort. Instead of relying on electricity, these units use solar panels to draw energy from their surroundings–an efficient and cost-effective solution.

Duct wrap is another staple of the HVAC industry that is used to reduce energy loss that can occur in air ducts. Unlike regular duct wrap, quiet duct wrap is made from recycled denim reduced from landfills. Quiet duct wraps also prevent irritants or other organic compounds from reducing indoor air quality.

The dual-fuel heat pump is a great solution that uses a combination of fuel types. The dual-fuel heat pump uses both electricity and gas to generate efficient heating and cooling. For homeowners who are concerned about the reliability and power of sustainable systems, the dual-fuel heat pump is one to count on. The pump uses electricity above 1.67 degrees Celsius, but if the temperature drops lower, the pump resorts to gas to heat the home. In that way, sustainable systems provide powerful solutions without compromising energy-efficient efforts.

The Future of Sustainability for Those in HVAC College

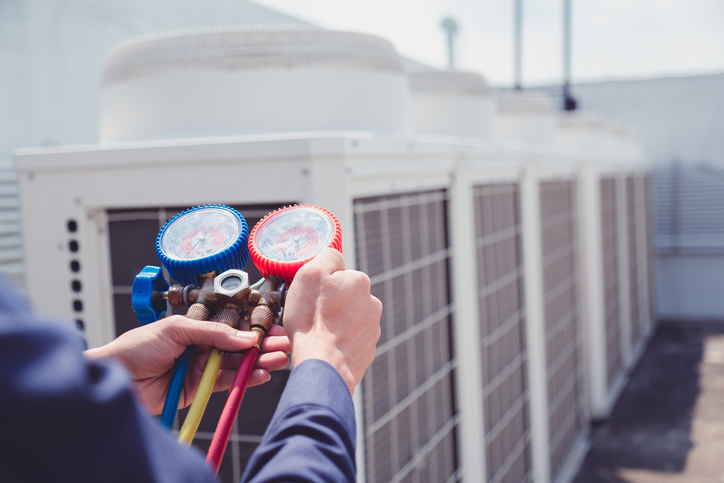

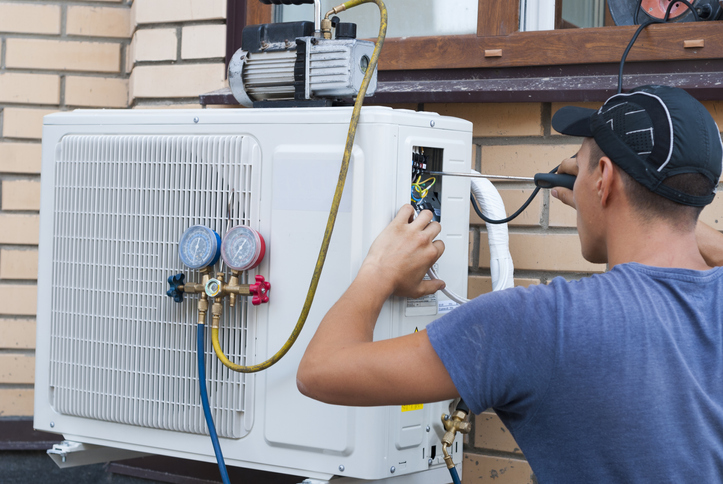

Students in HVAC technician courses will work with numerous types of equipment to construct and maintain HVAC systems–including: measurement gauges, refrigerant lines, and air ducts. Voltmeters, thermometers, pressure gauges, and other testing devices are used to check airflow, refrigerant pressure, electrical circuits, and other components. Knowing how to apply these tools and materials to sustainable solutions is valuable to stay ahead of the industry. To become more sustainable, construction technicians should consider the bigger picture and think in terms of building integration. By choosing the right products, materials, and building designs, technicians can push for a more sustainable future for the construction industry.

Are you interested in attending HVAC college?

Contact NATS today to learn more about our program!

If you’re considering launching a career as an HVAC (heating, ventilation and air conditioning) technician, you’ll be entering an exciting field where your skills will be in-demand. On the job, your duties might include installing HVAC units, conducting routine maintenance examinations, replacing broken components, and more. Throughout your career, it’s important to prioritize your safety, as HVAC technicians are often exposed to hazardous materials and conditions while on the job. Chemicals such as refrigerants and contaminants–including dirt and debris–are all common to encounter as an HVAC technician. With this in mind, it becomes key to wear the proper safety gear to protect you from harm.

Read on to discover what you should have on hand to stay safe as an HVAC technician.

After Finishing HVAC College, Wear Protective Gear

As an HVAC technician, it’s important to wear clothing that protects you from exposure to both chemicals and contaminants. On the job, be sure to wear a long-sleeved shirt and long pants so as not to leave any skin vulnerable. Additionally, ensure that your clothing is free of synthetic fibers, as they’re more flammable. After graduating from HVAC school, it’s also important to wear the right boots, as proper footwear is necessary to protect your feet from the heavy machinery you’ll be working with. You’ll also need safety goggles to protect your eyes from debris, and earplugs to prevent hearing damage due to the power tools used in HVAC work. Lastly, a thick pair of gloves will keep your fingers safe from any injuries that could result from handling sharp wires or pipes.

Use the Right Tools

When you use the right tools, your safety will be enhanced throughout your career. There are a few critical tools that enable you to perform any job in adherence with industry standards—reducing the risk of malfunctions that might otherwise pose a threat to your safety. As a graduate of HVAC college, you should always have the following tools in your bag:

- Clamp metre

- Anemometre

- Wrench

- Vacuum gauge

- Refrigerant leak detector

- Wire stripper

While it’s important to have these tools on hand, it’s important to examine the quality of your tools before beginning any repair or installation. By ensuring that your tools are in good working order, you’ll be able to avoid making any dangerous mistakes on the job.

Follow these Practices When Handling Chemicals

Throughout your career as an HVAC technician, you’ll be working with and transporting many different chemicals. In addition to wearing the right safety gear, it’s also important to know how to handle chemicals on the job to reduce your risk of injury. When using gas cylinders, make sure to inspect them before filling them up, and check to make sure there are no signs of leaks or damage. You should also not have gas cylinders in your van in hot weather, as this can increase the risk of explosion. When working with any detergents, refrigerants, solvents, or other cleaning liquids, make sure to wear goggles and a protective mask over your face to avoid exposing yourself to chemicals.

With these safety rules in mind, you’ll be ready for a long career as an HVAC technician.

Thinking about enrolling in HVAC technician courses?

Launch your career with a program at the North American Trade Schools!

As summer approaches, an air conditioner becomes one of the most essential home appliances. In order to keep cool in hot temperatures, people rely on their AC unit to deliver cold air right into their homes. But what happens when this appliance starts to leak? It’s not uncommon for an air conditioner to develop such a problem over time–especially if it hasn’t been properly maintained or is being used constantly. Air conditioner leakage can occur for a variety of reasons, but the good news is that a leak can almost always be fixed.

If you’re considering a career as an HVAC technician, knowing the most common culprits behind a leak can help you to quickly identify the source of a client’s problem: quickly restoring the flow of cool air within their homes!

Read on to discover six common causes of air conditioner leakage.

1. During Your HVAC Career, Be Aware That a Broken Pump May Cause a Leak

Within an air conditioner unit, the condensation pump is a device that serves to drain water in order to prevent a leak. However, this pump can actually cause a leak if it isn’t working properly. Most pumps are equipped with a float switch, which will turn on when the water gets to a certain level. If this switch has become stuck due to a buildup of debris or scum, it might not work. This lack of functioning can in turn result in dripping water from the unit. If you come across such a situation in your HVAC career, you can try cleaning the switch with bleach. If it still doesn’t turn on, chances are the pump needs replacing.

2. Drain Pan Issues Can Cause Leakage

Located beneath the indoor air handler, the drain pan functions as a trap for condensation created by the air conditioner. It connects to a drain pipe, which transfers the condensate outside to prevent moisture buildup around the unit. If the drain pan is rusting, cracked, or overflowing, this is likely to lead to a leak problem. Check the drain pan for leaks by turning off the AC unit and inspecting the pan for signs of rust, cracks, or debris buildup. If the drain pan is the culprit, this component of the air conditioner can easily be replaced.

3. If the Evaporator Coils Are Frozen, Leaking Will Follow

Evaporator coils can be found inside the door of the air conditioner unit. Refrigerant flows through these coils to deliver cool air through the vents. But if the evaporator coils freeze, ice will form and create a leak. These coils may freeze due to restricted air flow, a buildup of dirt or debris, blocked vents, or a lack of refrigerant. When you become an HVAC technician, you can identify frozen evaporator coils by checking whether there is ice or frost within the unit. From there, you can determine the source of the problem by checking the refrigerant levels, filter, vents, and other components to ensure that air is moving properly through the coils.

4. An Air Leak is One of the Most Common Problems

When an air leak occurs, air escapes around the vents of the air conditioner rather than through the designated path. This air flow can cause condensation to appear where it shouldn’t, leading to dripping from the AC unit. Air leaks can happen over time if a unit isn’t properly maintained. The good news is they can typically be fixed, simply with caulk, by sealing up the sides of the vent where air is escaping.

5. Look Out for a Blocked Condensation Drain Line

The condensation drain line attaches to the drain pan to transfer condensation outside–preventing leakage from occurring indoors. Over time, the drain line can accumulate debris or be exposed to algae or fungi growth. If the drip pan is overflowing but intact, it’s likely that the source of the leak is a clogged condensation drain line. Luckily, a blockage can typically be fixed by clearing the drain line using vinegar or another solution.

These are just some of the sources of leakage in a home’s AC unit. During your HVAC career, you can refer to these common underlying issues as possible causes when it comes to developing a solution for a client’s leaking air conditioner.

Are you interested in attending HVAC school?

Explore programs with NATS to launch your career today!

While propane isn’t the most commonly used source of energy for a home, its use has been growing in popularity in recent years. Propane is used to fuel both home-heating furnaces and water heaters. It is also beneficial due to the lower amount of greenhouse gas emissions it produces, as well as its potential as a less costly source of energy. In a propane heating system, propane is stored in a designated tank. This is fitted to a home’s gas line and then transferred to the furnace, which delivers heat to the rest of the home.

While propane isn’t the most commonly used source of energy for a home, its use has been growing in popularity in recent years. Propane is used to fuel both home-heating furnaces and water heaters. It is also beneficial due to the lower amount of greenhouse gas emissions it produces, as well as its potential as a less costly source of energy. In a propane heating system, propane is stored in a designated tank. This is fitted to a home’s gas line and then transferred to the furnace, which delivers heat to the rest of the home.

Propane is a convenient source of heat for a home, but it’s important to know how to maintain a propane heating system once it’s installed to ensure that it remains safe and effective. If you’re interested in a career as an HVAC technician, read on to discover three tips for maintaining a propane heating system.

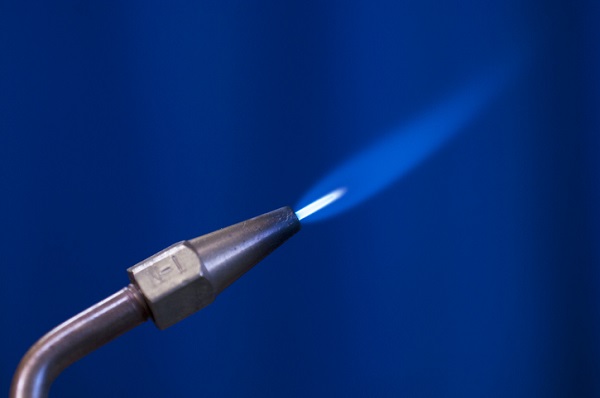

1. HVAC College Graduates Should Pay Attention to a Propane Heating System’s Pilot Light

Most propane heating systems operate through the use of a pilot light, which is a small flame that burns continuously. After HVAC school, it’s important to be familiar with how a propane heating system’s pilot light works in order to properly maintain these systems. In a propane heating system, the pilot light is located at the burner of the heating appliance that the propane fuel is being used for. The pilot light is also responsible for igniting the propane fuel to provide heat.

When maintaining a propane system, check the colour of the pilot light. A pilot light’s flame should be blue in colour. But if it appears to be orange or yellow, the pilot tube may need to be cleaned. Additionally, if the pilot light frequently extinguishes, this could signal a larger problem with the propane heating system. In this case, all connections and tubes should be examined to ensure that there isn’t a leak.

2. A Propane Heating System Needs Regular Service

One of the most important things to know about propane heating systems is that they may require more regular maintenance than other heating systems. A propane tank can be regularly serviced by checking the tank’s fuel gauge. When this gauge indicates that there’s less than 20% of fuel remaining, it’s time for a refill. Additionally, it’s important to examine the tank itself regularly by checking the tightness of the connecting pipes and ensuring that there are sufficient levels of pressure. Make sure that the area around the tank is clear of any forms of clutter. If there are flammable materials in close proximity of the tank, remove them in order to reduce the risk of fire.

3. Take Measures to Prevent Leakage

While a propane leak is uncommon, graduates of HVAC technician courses should be proactive in preventing leakage. A propane leak can be extremely dangerous, as propane is flammable and can increase the risk of fire within a home. The chances of a leak in a propane system can be reduced by tightening and protecting the propane tank’s fittings. Where the gas line connects to the propane tank, ensure that the connection is properly sealed by using a wrench to tighten the connection. If a leak is suspected, the main gas valve should be turned off immediately in order to safely address the problem.

When properly maintained, propane systems can be an efficient source of heat for a client’s home. During your HVAC technician career, take the above steps to ensure that your client’s propane heating system is working safely and effectively.

Are you ready to enroll in HVAC college?

Get the training you need at the North American Trade Schools. Start exploring today!

HVAC & The Environment: What You Should Know If You’re Pursuing an HVAC Career

March 10, 2021

Heating, ventilation and air conditioning (HVAC) systems have an essential function. They keep our homes cool in the summer and warm in the winter, in addition to regulating the quality and movement of the air that we’re breathing indoors. While HVAC systems aren’t the home appliances with the most severe environmental impact, there are still a few ways that HVAC systems can contribute negatively to the environment. HVAC systems may use refrigerants that can damage the ozone layer, and they also use electricity, the consumption of which burns fossil fuels and contributes to ozone depletion.

While HVAC systems can cause environmental harm, there are many solutions offered today which have the potential to reduce the impact HVAC systems can have on the environment. Some of these solutions can be implemented by HVAC technicians themselves. If you’re interested in becoming an HVAC technician, here’s what you need to know about the environmental impact of these systems and the solutions available today.

Those in an HVAC Career Should Know That HVAC Systems Can Emit Harmful Refrigerants

Air conditioning systems rely on cooling agents, or refrigerants, to drive cold air into homes, but these cooling agents have a known negative environmental impact. Hydro-chlorofluorocarbons (HCFCs), hydro-fluorocarbons (HFCs) and chlorofluorocarbons (CFCs) are all refrigerants that have been reported to contribute to ozone depletion and global warming, as these compounds are greenhouse gases. In Canada, Federal Halocarbon Regulations, 2003, bans the release of halocarbons from air conditioning systems in quantities over 0.1 kg of halocarbon per 01. kg of air, but these refrigerants are still being released into the atmosphere in lower quantities. Freon (R-22), a commonly used HCFC, has been banned in Canada for use in newly manufactured HVAC systems, and Puron (R-410A), a less-harmful HFC, is now more commonly used. However, this refrigerant still contributes to direct and indirect greenhouse gas emissions.

While it is difficult to control the emission of refrigerants into the atmosphere due to the range of HVAC systems in use today, advancements in technology have the potential to reduce their environmental impact. If you want to become a HVAC technician, you’ll probably become familiar with R-32 as a possible solution. R-32, or difluoromethane, is an HFC refrigerant known to have a lower impact on greenhouse gas emission than R-410A, and is being explored by HVAC engineers as an option to reduce the environmental impact of HVAC systems. It has been found that R-32 can even be used to make these systems more energy efficient, as it has better thermodynamic properties. In the future, developments in the use of alternative refrigerants such as R-32 have the potential to reduce the amount of greenhouse gases in the atmosphere as a result of HVAC systems.

HVAC Systems Use Energy

It’s important to be aware that HVAC systems consume high amounts of energy. Depending on the type of system and the season, an air conditioning system can consume around 3000 to 5000 watts of electricity every hour. Electricity consumption results in the burning of fossil fuels and the release of carbon dioxide into the atmosphere, a major cause of ozone layer depletion. One way to determine how much energy an air conditioning system is using is by checking its SEER rating. Older air conditioners have lower SEER ratings and tend to consume more energy.

As a way to reduce the amount of fossil fuels released, HVAC products that harness renewable energy sources are also becoming a more popular option. Renewable energy sources such as solar and geothermal energy can reduce the environmental impact of HVAC systems by using sources of power that don’t burn fossil fuels. Solar energy harnesses energy from sunlight rather than from fossil fuels to power HVAC systems, while geothermal heat pumps convert natural energy stored underground for use.

Small-Scale Solutions to Reduce the Environmental Impact of HVAC Systems

The environmental impact of HVAC systems can be reduced on a small scale, and as a professional in an HVAC career, this is an area where your services are especially useful to clients looking to reduce their own personal energy consumption and greenhouse gas emissions. The efficiency of an HVAC system depends on the equipment being used. If a system’s equipment is outdated, chances are it’s using more energy or emitting a greater quantity of harmful refrigerants. Advising environmentally-conscious clients to replace old HVAC systems with an updated, energy efficient system can reduce the negative impact of older units.

Additionally, HVAC systems should be regularly maintained in order to prevent excess emissions. Air filters should be replaced regularly, ducts and pipes should be inspected for leaks, and valves and steam traps should be examined for efficiency.

If you want to be equipped with the ability to make HVAC systems less harmful for the environment, a program at the North American Trade Schools (NATS) could be right for you. Jason, a graduate of the North American Trade Schools HVAC technician program, says he chose NATS because of its reputation as a “hands-on school.” He notes, “They teach you what you need to know and then you apply your knowledge.” Practical, experiential training enables HVAC technicians to apply their newly learned skills in the field in innovative ways. That includes approaches that may help to reduce the environmental impact of HVAC systems.

Are you interested in attending HVAC school?

The North American Trade Schools program could be right for you!

Working within the heating, ventilation, and air conditioning (HVAC) industry is a rewarding career path. However, it takes more than classroom learning to gain the confidence you need to feel comfortable on the job. In order to become successful in this field, it’s important that you also get hands-on training and experience.

Working within the heating, ventilation, and air conditioning (HVAC) industry is a rewarding career path. However, it takes more than classroom learning to gain the confidence you need to feel comfortable on the job. In order to become successful in this field, it’s important that you also get hands-on training and experience.

Being an HVAC technician is all about knowing how to diagnose a situation and use the correct tools and equipment to perform the task at hand–whether that’s installing, maintaining, or repairing a system. When choosing an HVAC program, make sure that you’re choosing one that offers hands-on training to equip you with the experience necessary to handle all kinds of situations.

Here’s more on why hands-on training is necessary for aspiring HVAC technicians.

Hands-On HVAC Technician Courses Promote Problem-Solving Skills

A good HVAC technician should be able to apply the knowledge they learn in the classroom to real-world situations, and be able to actively solve the problem at hand. The only way to get better at problem-solving on the job is to gain experience at an HVAC college–offering students the opportunity to participate in hands-on training. At North American Trade Schools (NATS), students receive hands-on training in the lab in addition to the information they learn in the classroom. They can expect to work with testing devices and various types of equipment. This helps them to gain first-hand experience with common problems encountered on the job.

Greater Retention of Information

Learning by doing has been proven to be a fool-proof way to remember information. When engaging in hands-on learning, students enrolled in HVAC technician training have the opportunity to familiarize themselves with common materials and equipment of the trade, and get to practice using these tools. Because they’re learning by doing with hands-on training, students are more likely to retain what they’ve experienced, and can easily access and apply that knowledge to situations on the job.

Students Will Gain Familiarity with Safety Protocols

Within this field, there are always risks and safety hazards that may be encountered. Working within the real-world environment offered through hands-on training gives students in HVAC technician courses the chance to practice following safety protocols, and allows them to better understand the risks that go along with the job.

Get Training From Industry Experts

As an HVAC technician student, much of what you learn will depend on the advice and experience of others. It’s important to get hands-on training from experienced teachers in order to learn as much as possible about the field. At NATS, the instructors supervising your training are industry experts. Input from these seasoned professionals proved invaluable to NATS welding graduate Emily Harrison, who said her “favourite thing about the campus was the knowledge of the teachers and how much practical work you were able to do. It was very helpful.”

Receiving hands-on training from experienced instructors will ensure that all your questions are answered, making you that much more ready to tackle on-the-job challenges.

Are you interested in attending HVAC school to prepare you for this role with hands-on training?

Check out program options from North American Trade Schools today.

What Those with HVAC Technician Training Should Know About the Benefits of Preventative Maintenance

September 15, 2020 There’s nothing worse than the AC breaking down on a blazing hot day—apart from maybe the heating system fizzling out when it’s a frigid -30 degrees! HVAC technicians become very popular individuals at the height of summer and winter, serving to rescue home and business owners from uncomfortable temperatures by performing emergency repairs as they come up.

There’s nothing worse than the AC breaking down on a blazing hot day—apart from maybe the heating system fizzling out when it’s a frigid -30 degrees! HVAC technicians become very popular individuals at the height of summer and winter, serving to rescue home and business owners from uncomfortable temperatures by performing emergency repairs as they come up.

Keeping HVAC units in good working order through routine checkups is another important role of the technician. Here’s why routine maintenance practices are important for keeping these systems in their best shape all year round!

Routine Maintenance Helps Owners Breathe Easier

Respiratory problems like asthma and bronchitis can often be traced back to the living conditions of the home, with the dirty HVAC unit a prime culprit in many cases. The problem comes from condensation forming in the coils and ducts of the AC unit, which can lead to all kinds of harmful mold and bacteria growth.

Customers who keep to a routine maintenance schedule for their HVAC units are ensuring that all of the harmful contaminants that may have built up inside the system are eliminated. A service technician is responsible for cleaning filters, coils, and other components of the unit on a routine visit, which leads to a cleaner unit, thereby improving air quality.

A Well-Maintained System Can Save the Owner Money

What would a home or business owner care more about than breathing clean air? How about more money in the old pocketbook! If you’re interested in HVAC technician training, you should know that keeping an HVAC system in good working order can help the owner save money by optimizing efficiency to keep energy costs down. A well-maintained HVAC system uses a lot less energy and puts less wear and tear on the machinery of the HVAC unit, running a good 20% more efficiently than a neglected unit.

Regular checkups in the fall and spring can keep efficiency strong, and help an owner get a good ten years out of their HVAC investment. Routine checkups also allow the service tech to catch a small problem needing a quick, inexpensive fix before it turns into a much more complicated problem requiring lots of work—and lots of coin to repair.

Fewer Emergency Breakdowns and More Warranty Opportunities

People run their HVAC systems pretty hard in the summer and winter months, which can lead to breakdowns. These machines are designed to handle the energy levels the owner demands, but only if the unit is being looked after properly. If you’re seeking your HVAC diploma, you should know that breakdown prevention during the hottest and coldest times of the year is reliant on keeping routine maintenance and inspection checks.

By keeping up regular twice-a-year visits, the owner may even be lucky enough to discover that a part that needs work or full replacement is still under warranty. Longer waiting times between visits reduce the opportunity to spot a problem before a warranty period has reached its expiration date.

What Are Some Maintenance Tasks Those Attending HVAC School Should Know About?

There are a few things to watch out for during routine maintenance checks. On heating systems, the tech will need to check: fuel lines and power sources, inspect combustion chambers, inspect the heat exchanger for cracks or other evidence of damage, as well as check for carbon monoxide leaks.

On cooling systems, the tech needs to take a look at the fans and blowers, thermostat, system controls, ductwork systems, evaporator and condenser coils, and condensate drains to ensure everything is clean, undamaged, and functioning properly. Additionally, fans and motors must be lubricated, and refrigerant levels must be filled.

All of these tasks need to be performed at regular intervals to ensure that systems keep running properly.

Are you interested in training at HVAC school?

Contact North American Trade Schools today to learn more!

It’s not just the quality of an HVAC unit that counts, but how it’s installed. As an HVAC technician, your responsibility is to install these systems and detect any issues that can arise within their many different components and figure out how to correct them. However, there are several mistakes you can find yourself making if you aren’t careful with the installation process.

Since learning how to maintain and install HVAC systems are a significant component of your job, it’s just as important to know what not to do as it is to learn best installation practices. Here are some of the more common mistakes you may find yourself making after your HVAC training.

Ductwork is One of the Most Important Factors to Watch After HVAC School

It’s important to be sure you choose the correctly-sized duct for the HVAC unit you’re installing, and use high-quality materials in the process (e.g. using a heavy-duty sealant instead of tape, and adding R-6 insulation wrap).

If you don’t, it can create issues with both air flow and leaking, and potentially result in gaps, dust, loud noises, or an overheating furnace. As a result, the unit itself won’t function properly, and those living in the home will likely see their energy bills rise. Not only that, but up to 30% of the HVAC unit’s overall output can be compromised when not properly insulated.

When it Comes to the Furnace, Size is Everything

By “size is also everything”, we don’t mean they need to be as big as you can possibly get them. Rather, the important thing to consider after finishing your HVAC training is to find a furnace that is sized proportionately to the one previously in place, and is also a newer model.

This not only helps with the flow of air in the home, but with the system’s efficiency as a whole. Should you not pick a correctly sized furnace, problems could occur. This includes the unit overworking itself to provide better cooling or heat if too small, or uneven temperatures if too big. However, be sure to double-check that the size calculations are correct, even if it’s technically the same size as the previous furnace.

Make Sure Air is Properly Distributed at All Times

This is one of the most crucial parts of a successful HVAC installation, as it can otherwise lead to uneven cooling or heating. HVAC school students should be aware that proper air distribution design is a must, and that the ductwork is symmetrical in size to the unit’s output capacity.

To achieve this, apply new ductwork rather than the preexisting one, and be sure it’s distributing air evenly. Another of the more important aspects to keep in mind is proper ventilation. You’ll need to ensure the HVAC unit you’ve installed has a strong balance of both hot and cold air, and that the air is balanced and flows cleanly throughout the home.

Want to start your HVAC technician training?

Contact North American Trade Schools today!

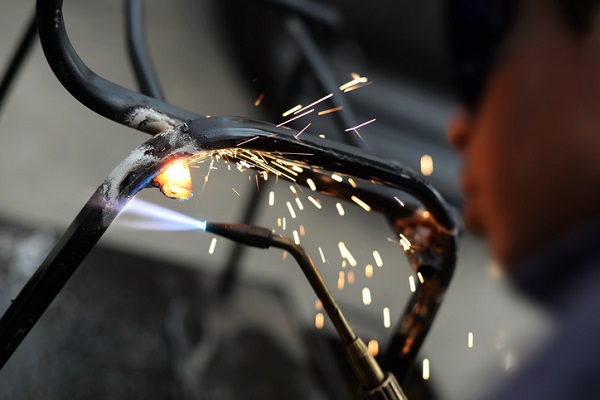

Acetylene torches are to HVAC (heating, ventilation, and air conditioning) technicians what calculators are to mathematicians: an essential tool with many uses. Providing one of the most powerful methods of welding and cutting metals, this tool is widely used in the industry to fix leaks and solder line sets.

But like any gas-powered tool, if you want to use it properly, there are a few key things you’ll need to know and some safety regulations you’ll need to follow. Read on to learn all about acetylene torches and the role they will play in your HVAC career.

What is Acetylene & How Can You Use it?

As one would expect, the basis of an acetylene torch is the hydrocarbon compound called Acetylene. What you may not know is that this element can get really, really hot. In fact, acetylene produces the third hottest chemical flame, and can reach an astounding 3,300 degrees Celsius when mixed with oxygen.

Acetylene is a highly unstable compound. However, once you combine it with another chemical, you can use acetylene safely and easily while still benefiting from its thermal capabilities. Oxygen is the substance most commonly combined with acetylene – but it’s important to note that the term “acetylene torch” can also be used to describe any type of oxy-fuel torch where other gases such as propane and propylene are used.

Regardless of which chemicals are involved, the two gases are present in two separate gas tanks, which are connected to the torch by two metal hoses. The flame is produced when these two gases are passed through the hoses and combined. When this flame contacts metal, it produces a chemical reaction that initiates a process known as oxyfuel cutting.

Acetylene Torch Safety Regulations

As with any power tool, it’s important to know how to safely handle an acetylene torch before you put it to use. One advantage of HVAC school is learning the safest ways to handle the equipment you’ll encounter in your career. Graduates of North American Trade Schools will learn the safety regulations and precautions they need to take to operate an acetylene torch.

One procedure you will need to learn is how to check your acetylene torch before using it to make sure it’s functioning properly. Firstly, you should check that the torch is closed, and ensure that the pressure adjustment screws are blacked out. Then you can separately open the gas cylinder valves and adjust the regulator p/a screws to change the pressure settings. Next, you can open and close valves separately and make any other changes to the pressure settings on the regulators.

HVAC Technician Training 101: Using an Acetylene Torch

HVAC technician training will allow you to learn how to use these power tools through a hands-on approach, but it’s good practice to know a bit about the steps in using them before you begin your studies.

To use an acetylene torch, you’ll first have to light it by purging the oxygen and fuel gas lines – separately – and opening the fuel gas valve slightly. Next, using a striker, ignite the flame. You can then adjust the gas flow to make the flame form a sharp tip. Now your acetylene torch is ready to use.

Once you’re finished with the torch, you can shut it down by closing the oxygen and fuel gas torch valves. If you don’t plan on using the torch for a while, make sure that all the regulator gauges read zero.

Want to earn your HVAC diploma?

Contact North American Trade Schools for more information!

Fuel gases help fuel heating systems, provide energy for transportation, and are used for welding—but what are they, really? Fuel gases are gases that, when mixed with oxygen or air, become combustible. They can apply to several different processes, and can be used for a number of different industrial applications. Since it’s very important for students training to become an HVAC technician to know how to practice the safest possible gas-handling procedures, learning the basics about fuel gases is a good idea.

While there’s a lot to learn about fuel gases, it’s worth knowing some of the basics beforehand, so that students have a solid idea of how fuel gases apply to heating. Here’s what students in HVAC training should know.

HVAC School Students Should Familiarize Themselves With the Different Types Used

One of the most important things to remember about fuel gases is that there are a number of different types that can be used. Some of the most commonly used are hydrogen, carbon monoxide, and ethylene. However, we’ll be focusing specifically on acetylene, methane, propane, and propylene. These four in particular are worth remembering for those in HVAC training, because each of them are comprised of hydrocarbons, either partially or in full.

Acetylene is considered the most efficient and productive fuel gas, producing the hottest and most concentrated flame. It can also be used for both welding and cutting, the only kind of commercial fuel gas that can do so. Methane is what natural gas is primarily made of, and is most often used for heating. Its combustion properties can also vary, and can be used for cutting purposes in some cases.

Propane has a lower flame temperature than acetylene when mixed with oxygen, and has the lowest flammability range among the most common fuel gases, but can be used for various purposes such as heating, brazing, melting and drying. Lastly, propylene’s double bond means it burns hotter and has a higher flame temperature than propane, and is often used during situations that call for a higher process performance.

Different Fuel Gases Have Different Heating Values and Other Properties Between Them

Since a big part of HVAC school involves learning about fuel gases and their respective characteristics and properties, it’s worth familiarizing yourself with the different heat values between each type of fuel gas. For example, acetylene has a gross heating value of 1,498 btu/ft3 and 21,569 btu/lb (British thermal units per cubic feet and pounds). Meanwhile, propane has a gross heating value of 2,572 btu/ft3 and 21,564 btu/lb, and propylene has 2,336 btu/ft3 and 21,042 btu/lb. Therefore, acetylene needs much less than propane or propylene to produce the necessary heat.

It’s also worth remembering that fuel gases each have different carbon to hydrogen atom ratios. This means that the efficient burning of the gas will require various amounts of oxygen to be used depending on the fuel gas type. Furthermore, some fuel gases are natural, while others are manufactured. Natural fuel gas largely consists of methane, while gases like ethane, propane and butane are considered natural gases. Natural gas is also considered the most commonly used fuel gas type today. Meanwhile, manufactured types of fuel gases include hydrogen, acetylene, biogas, coal gas, and blast furnace gas among others.

Want to start your HVAC technician training?

Contact North American Trade Schools for more information!