Tag: HVAC technician training

In recent years, we’ve seen record-high temperatures across the globe. Many homeowners are recognizing the importance of good ventilation and cooling units–and that’s where you come in as an aspiring HVAC technician.

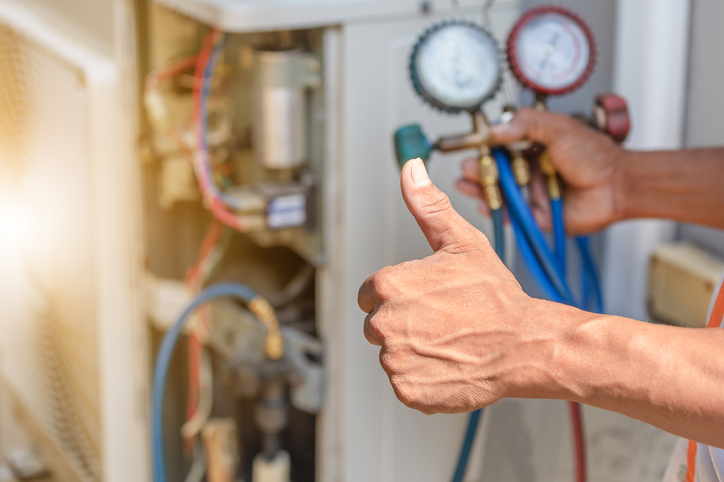

HVAC technicians are responsible for the installation, maintenance, and repair of heating, ventilation, and air conditioning systems. Here are a few installation tips to remember when installing HVAC units, and how our HVAC technician program can help you launch a successful career in this industry!

1. Start by Determining Your Heating and Cooling Loads

The heating and cooling load refers to the rate at which heat should be supplied to or removed from a space in order to maintain a particular temperature range. Several factors go into determining this like the location, size, and age of a home. In addition, you’ll need to take into account the materials that were used to make up a home, the number of doors and windows, the amount of direct sunlight, the amount of shade, and whether or not the homeowners have special needs due to allergies and other health conditions.

Once you’ve come up with this important information, you can go on to take a look at the ductwork that’s been done and make any needed repairs or replacements. As you’ll learn in HVAC technician training, poor ductwork can cause imbalances and, as a result, block airflow and decrease air quality. To boost your ductwork, you may consider adding insulation that can improve the performance of HVAC systems.

2. Be Sure That You’ve Chosen the Correct Sized Unit

A large unit is not always better. If a system is too large for a homeowner’s space, it actually becomes inefficient. In fact, systems that are too large for a particular space can experience degradation faster, which will affect the longevity and performance of the unit. That being said, a small unit wouldn’t be appropriate for a large space as it will not effectively heat or cool the space.

How can you ensure that you’ve sized the unit correctly? First, determine the square footage of the space. Then, multiply the square footage by 25 BTU (British thermal units), the rough amount of energy it takes to heat or cool one square foot. This will give you your base BTU amount. Finally, take the height of the ceilings into account. If the ceilings are above 8 feet, multiply the base BTU amount by 1.25. This is a very basic calculation that does not take into account the climate, amount of people living in the home, or the number and placement of doors and windows. You’ll learn more about this process in HVAC school.

3. Make it a Habit to Check Your Lines After HVAC Technician Training

Refrigerant lines connect an outdoor air conditioner or heat pump to the indoor evaporator coil. It’s essential to check these lines for leaks. If you find refrigerant lines that are in poor condition, be sure to run high-quality replacement lines in a location that provides easy access. In the HVAC Technician Diploma program at NATS, you’ll learn how to install and maintain HVAC systems and work with tools like metal snips, electric drills, testing devices, and more. Students can write their G3 gas technician exam after the first module and the G2 gas technician exam after graduation.

Interested in our HVAC technician diploma program?

Contact NATS to learn more!

For future HVAC technicians just completing their training, there are many exciting career opportunities available. Graduates can look for jobs as HVAC Installers, Technicians, Maintenance Assistants, or Maintenance Technicians. In Ontario, job opportunities in HVAC are good. Part of the reason for this is that population growth is driving the need for more buildings, especially in certain urban areas.

For future HVAC technicians just completing their training, there are many exciting career opportunities available. Graduates can look for jobs as HVAC Installers, Technicians, Maintenance Assistants, or Maintenance Technicians. In Ontario, job opportunities in HVAC are good. Part of the reason for this is that population growth is driving the need for more buildings, especially in certain urban areas.

When interviewing for your first job in HVAC, it’s important to know what employers are looking for and how to present yourself in order to ensure you’re putting your best foot forward. Read on for a few tips on how to ace your interview and land the job.

Know How to Highlight Your HVAC Training in the Interview

When interviewing for an HVAC career, it’s important to research the company you’re applying to, so that you know a bit more about what they could be expecting from you. Try to determine the types of services they provide (whether they’re primarily residential or commercial), what kinds of locations they cater to, and what kinds of equipment they typically utilize. This kind of information will help you to highlight the skills you have that will be most impressive to the employer.

Graduates of hands-on training programs like the North American Trade Schools’ HVAC technician training program can reference the marketable skills they know will impress their potential employer simply by doing a bit of research on the company they’re applying for.

Become Familiar with Possible Questions You Might Be Asked

While you might not be able to anticipate every question, it’s good to come prepared with a few possible interview questions. You’ll probably be asked simple but important questions like what motivates you, what about their company interests you, and other questions which allow them to get to know you as a person. They also might ask you some questions more relevant to the HVAC industry, such as inquiring why you’re interested in HVAC, what your driving record is like, and more. Prepare answers that show you’re ready for an HVAC career and have excelled in your HVAC training.

Prepare Questions to Ask Your Potential Employer

It’s also good to have in mind a list of questions that you would like to ask during the interview. These questions should be about the company specifically, demonstrating that you’ve taken the time to get to know them and showing them that you’re interested. Your questions could be about the company’s expectations for you as an employee, what a typical day on the job might look like, what about the company is especially unique, or any other company-related questions you might have.

A “Thank You” Never Hurts

Lastly, remember to thank the interviewer after you’ve finished, in addition to sending a follow-up thank you email. Make sure they know you’re interested in the job!

Think you have what it takes to become an HVAC technician?

Check out the North American Trade Schools program options today.

What Those with HVAC Technician Training Should Know About the Benefits of Preventative Maintenance

September 15, 2020 There’s nothing worse than the AC breaking down on a blazing hot day—apart from maybe the heating system fizzling out when it’s a frigid -30 degrees! HVAC technicians become very popular individuals at the height of summer and winter, serving to rescue home and business owners from uncomfortable temperatures by performing emergency repairs as they come up.

There’s nothing worse than the AC breaking down on a blazing hot day—apart from maybe the heating system fizzling out when it’s a frigid -30 degrees! HVAC technicians become very popular individuals at the height of summer and winter, serving to rescue home and business owners from uncomfortable temperatures by performing emergency repairs as they come up.

Keeping HVAC units in good working order through routine checkups is another important role of the technician. Here’s why routine maintenance practices are important for keeping these systems in their best shape all year round!

Routine Maintenance Helps Owners Breathe Easier

Respiratory problems like asthma and bronchitis can often be traced back to the living conditions of the home, with the dirty HVAC unit a prime culprit in many cases. The problem comes from condensation forming in the coils and ducts of the AC unit, which can lead to all kinds of harmful mold and bacteria growth.

Customers who keep to a routine maintenance schedule for their HVAC units are ensuring that all of the harmful contaminants that may have built up inside the system are eliminated. A service technician is responsible for cleaning filters, coils, and other components of the unit on a routine visit, which leads to a cleaner unit, thereby improving air quality.

A Well-Maintained System Can Save the Owner Money

What would a home or business owner care more about than breathing clean air? How about more money in the old pocketbook! If you’re interested in HVAC technician training, you should know that keeping an HVAC system in good working order can help the owner save money by optimizing efficiency to keep energy costs down. A well-maintained HVAC system uses a lot less energy and puts less wear and tear on the machinery of the HVAC unit, running a good 20% more efficiently than a neglected unit.

Regular checkups in the fall and spring can keep efficiency strong, and help an owner get a good ten years out of their HVAC investment. Routine checkups also allow the service tech to catch a small problem needing a quick, inexpensive fix before it turns into a much more complicated problem requiring lots of work—and lots of coin to repair.

Fewer Emergency Breakdowns and More Warranty Opportunities

People run their HVAC systems pretty hard in the summer and winter months, which can lead to breakdowns. These machines are designed to handle the energy levels the owner demands, but only if the unit is being looked after properly. If you’re seeking your HVAC diploma, you should know that breakdown prevention during the hottest and coldest times of the year is reliant on keeping routine maintenance and inspection checks.

By keeping up regular twice-a-year visits, the owner may even be lucky enough to discover that a part that needs work or full replacement is still under warranty. Longer waiting times between visits reduce the opportunity to spot a problem before a warranty period has reached its expiration date.

What Are Some Maintenance Tasks Those Attending HVAC School Should Know About?

There are a few things to watch out for during routine maintenance checks. On heating systems, the tech will need to check: fuel lines and power sources, inspect combustion chambers, inspect the heat exchanger for cracks or other evidence of damage, as well as check for carbon monoxide leaks.

On cooling systems, the tech needs to take a look at the fans and blowers, thermostat, system controls, ductwork systems, evaporator and condenser coils, and condensate drains to ensure everything is clean, undamaged, and functioning properly. Additionally, fans and motors must be lubricated, and refrigerant levels must be filled.

All of these tasks need to be performed at regular intervals to ensure that systems keep running properly.

Are you interested in training at HVAC school?

Contact North American Trade Schools today to learn more!

It’s not just the quality of an HVAC unit that counts, but how it’s installed. As an HVAC technician, your responsibility is to install these systems and detect any issues that can arise within their many different components and figure out how to correct them. However, there are several mistakes you can find yourself making if you aren’t careful with the installation process.

Since learning how to maintain and install HVAC systems are a significant component of your job, it’s just as important to know what not to do as it is to learn best installation practices. Here are some of the more common mistakes you may find yourself making after your HVAC training.

Ductwork is One of the Most Important Factors to Watch After HVAC School

It’s important to be sure you choose the correctly-sized duct for the HVAC unit you’re installing, and use high-quality materials in the process (e.g. using a heavy-duty sealant instead of tape, and adding R-6 insulation wrap).

If you don’t, it can create issues with both air flow and leaking, and potentially result in gaps, dust, loud noises, or an overheating furnace. As a result, the unit itself won’t function properly, and those living in the home will likely see their energy bills rise. Not only that, but up to 30% of the HVAC unit’s overall output can be compromised when not properly insulated.

When it Comes to the Furnace, Size is Everything

By “size is also everything”, we don’t mean they need to be as big as you can possibly get them. Rather, the important thing to consider after finishing your HVAC training is to find a furnace that is sized proportionately to the one previously in place, and is also a newer model.

This not only helps with the flow of air in the home, but with the system’s efficiency as a whole. Should you not pick a correctly sized furnace, problems could occur. This includes the unit overworking itself to provide better cooling or heat if too small, or uneven temperatures if too big. However, be sure to double-check that the size calculations are correct, even if it’s technically the same size as the previous furnace.

Make Sure Air is Properly Distributed at All Times

This is one of the most crucial parts of a successful HVAC installation, as it can otherwise lead to uneven cooling or heating. HVAC school students should be aware that proper air distribution design is a must, and that the ductwork is symmetrical in size to the unit’s output capacity.

To achieve this, apply new ductwork rather than the preexisting one, and be sure it’s distributing air evenly. Another of the more important aspects to keep in mind is proper ventilation. You’ll need to ensure the HVAC unit you’ve installed has a strong balance of both hot and cold air, and that the air is balanced and flows cleanly throughout the home.

Want to start your HVAC technician training?

Contact North American Trade Schools today!

Since heat pumps are such a common tool in the heating, ventilation, and air conditioning (HVAC) industry, aspiring technicians should expect to become very familiar with them throughout their education and future career. Read on for an introduction to heat pumps to get you warmed up!

Learn How Heat Pumps Work With an HVAC Diploma

Heat pumps are not a new technology. In fact, the first heat pump was invented in 1948 by Robert C. Webber. Since then, the technology has been developed to resemble the air conditioning and heating units we have in our homes and offices today. HVAC technician courses will give you the opportunity to learn hands-on how this technology works.

Heat pumps can provide both heating and cooling services. In heating mode, heat is absorbed from outside by the condenser coil and transferred to the interior space via air vents. Even on cold winter days, heat pumps are able to collect warm air from outside. However, if there’s not enough warm air outside, heat pumps can use electric energy or an additional gas furnace to provide extra heat.

In air conditioning mode, the cycle is reversed. Warm air inside the house is pulled into the system with a motorized fan and transferred outside, usually behind or underneath the condenser coil. Cool and dehumidified air then enters the home through the air vents.

Heat Pumps are Energy Efficient

Eco-conscious homeowners will be relieved to discover that heat pumps are incredibly energy efficient. As you will learn in HVAC technician training, heat pumps generate 4 units of thermal energy per 1 unit of electricity used – that’s an efficiency rating of 400%!

In contrast, electrical heaters are 100% efficient, meaning that they generate 1 unit of thermal energy for every 1 unit of electricity. As well as this, heat pumps generate zero emissions, so are a great option for people that want to warm or cool their homes without damaging the planet.

Air Source vs. Ground Source Heat Pumps

As an HVAC technician, you will need to know about two main types of heat pumps: air source and ground source. Air source heat pumps are the most common type and absorb or reject heat from the outdoor air.

As the name suggests, ground source heat pumps get heat from the ground or from water. These are sometimes referred to as geothermal heat pumps and are actually slightly more efficient than air source systems. However, they are more expensive and complicated to install as the systems will need to be built into the soil around a home.

What are the Main Heat Pump Parts?

Air source and ground source heat pumps are made up of a number of components. These include:

- Compressor– to move the refrigerant through the system

- Control board – to control whether the system is in cooling or heating mode

- Condenser coil – to transfer heat outside in cooling mode

- Evaporator coil–to transfer heat inside in heating mode

- Refrigerant – a chemical substance that moves heat through the system

- Thermostat – to choose the desired temperature

Are you interested in a HVAC diploma?

Contact North American Trade Schools to find out more!

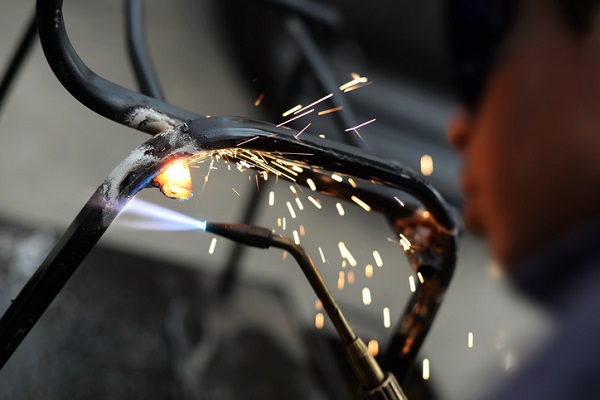

Acetylene torches are to HVAC (heating, ventilation, and air conditioning) technicians what calculators are to mathematicians: an essential tool with many uses. Providing one of the most powerful methods of welding and cutting metals, this tool is widely used in the industry to fix leaks and solder line sets.

But like any gas-powered tool, if you want to use it properly, there are a few key things you’ll need to know and some safety regulations you’ll need to follow. Read on to learn all about acetylene torches and the role they will play in your HVAC career.

What is Acetylene & How Can You Use it?

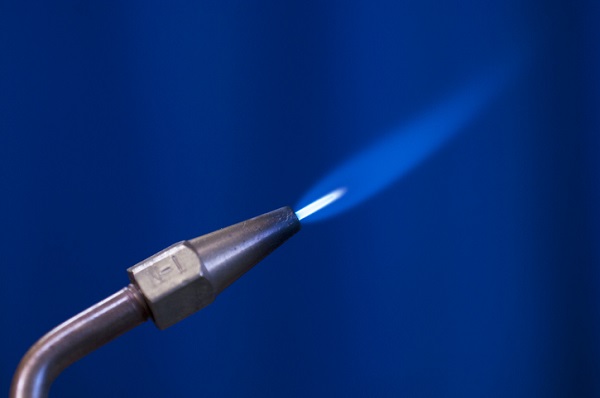

As one would expect, the basis of an acetylene torch is the hydrocarbon compound called Acetylene. What you may not know is that this element can get really, really hot. In fact, acetylene produces the third hottest chemical flame, and can reach an astounding 3,300 degrees Celsius when mixed with oxygen.

Acetylene is a highly unstable compound. However, once you combine it with another chemical, you can use acetylene safely and easily while still benefiting from its thermal capabilities. Oxygen is the substance most commonly combined with acetylene – but it’s important to note that the term “acetylene torch” can also be used to describe any type of oxy-fuel torch where other gases such as propane and propylene are used.

Regardless of which chemicals are involved, the two gases are present in two separate gas tanks, which are connected to the torch by two metal hoses. The flame is produced when these two gases are passed through the hoses and combined. When this flame contacts metal, it produces a chemical reaction that initiates a process known as oxyfuel cutting.

Acetylene Torch Safety Regulations

As with any power tool, it’s important to know how to safely handle an acetylene torch before you put it to use. One advantage of HVAC school is learning the safest ways to handle the equipment you’ll encounter in your career. Graduates of North American Trade Schools will learn the safety regulations and precautions they need to take to operate an acetylene torch.

One procedure you will need to learn is how to check your acetylene torch before using it to make sure it’s functioning properly. Firstly, you should check that the torch is closed, and ensure that the pressure adjustment screws are blacked out. Then you can separately open the gas cylinder valves and adjust the regulator p/a screws to change the pressure settings. Next, you can open and close valves separately and make any other changes to the pressure settings on the regulators.

HVAC Technician Training 101: Using an Acetylene Torch

HVAC technician training will allow you to learn how to use these power tools through a hands-on approach, but it’s good practice to know a bit about the steps in using them before you begin your studies.

To use an acetylene torch, you’ll first have to light it by purging the oxygen and fuel gas lines – separately – and opening the fuel gas valve slightly. Next, using a striker, ignite the flame. You can then adjust the gas flow to make the flame form a sharp tip. Now your acetylene torch is ready to use.

Once you’re finished with the torch, you can shut it down by closing the oxygen and fuel gas torch valves. If you don’t plan on using the torch for a while, make sure that all the regulator gauges read zero.

Want to earn your HVAC diploma?

Contact North American Trade Schools for more information!

Fuel gases help fuel heating systems, provide energy for transportation, and are used for welding—but what are they, really? Fuel gases are gases that, when mixed with oxygen or air, become combustible. They can apply to several different processes, and can be used for a number of different industrial applications. Since it’s very important for students training to become an HVAC technician to know how to practice the safest possible gas-handling procedures, learning the basics about fuel gases is a good idea.

While there’s a lot to learn about fuel gases, it’s worth knowing some of the basics beforehand, so that students have a solid idea of how fuel gases apply to heating. Here’s what students in HVAC training should know.

HVAC School Students Should Familiarize Themselves With the Different Types Used

One of the most important things to remember about fuel gases is that there are a number of different types that can be used. Some of the most commonly used are hydrogen, carbon monoxide, and ethylene. However, we’ll be focusing specifically on acetylene, methane, propane, and propylene. These four in particular are worth remembering for those in HVAC training, because each of them are comprised of hydrocarbons, either partially or in full.

Acetylene is considered the most efficient and productive fuel gas, producing the hottest and most concentrated flame. It can also be used for both welding and cutting, the only kind of commercial fuel gas that can do so. Methane is what natural gas is primarily made of, and is most often used for heating. Its combustion properties can also vary, and can be used for cutting purposes in some cases.

Propane has a lower flame temperature than acetylene when mixed with oxygen, and has the lowest flammability range among the most common fuel gases, but can be used for various purposes such as heating, brazing, melting and drying. Lastly, propylene’s double bond means it burns hotter and has a higher flame temperature than propane, and is often used during situations that call for a higher process performance.

Different Fuel Gases Have Different Heating Values and Other Properties Between Them

Since a big part of HVAC school involves learning about fuel gases and their respective characteristics and properties, it’s worth familiarizing yourself with the different heat values between each type of fuel gas. For example, acetylene has a gross heating value of 1,498 btu/ft3 and 21,569 btu/lb (British thermal units per cubic feet and pounds). Meanwhile, propane has a gross heating value of 2,572 btu/ft3 and 21,564 btu/lb, and propylene has 2,336 btu/ft3 and 21,042 btu/lb. Therefore, acetylene needs much less than propane or propylene to produce the necessary heat.

It’s also worth remembering that fuel gases each have different carbon to hydrogen atom ratios. This means that the efficient burning of the gas will require various amounts of oxygen to be used depending on the fuel gas type. Furthermore, some fuel gases are natural, while others are manufactured. Natural fuel gas largely consists of methane, while gases like ethane, propane and butane are considered natural gases. Natural gas is also considered the most commonly used fuel gas type today. Meanwhile, manufactured types of fuel gases include hydrogen, acetylene, biogas, coal gas, and blast furnace gas among others.

Want to start your HVAC technician training?

Contact North American Trade Schools for more information!

HVAC stands for heating, ventilation, and air conditioning, and as an HVAC technician you might be responsible for installing, maintaining, and repairing any of these systems. An HVAC diploma provides you with hands-on training in order to get you going in your career, no matter what type of system of you focus on.

One aspect of working as an HVAC technician is knowing how to use the right tools for the job. There are multiple instruments that you may encounter and utilize in your training or in your career, including testing devices.

Continue reading to discover a few of the testing devices frequently used by HVAC technicians.

1. An Infrared Thermometer Can Help You Spot Problems from a Distance

An infrared thermometer (IR) uses infrared technology to measure an object’s temperature from a distance. Sometimes called laser thermometers, IRs calculate the infrared emission of an object to determine its temperature. IRs may be used to quickly locate overheating circuits and equipment without requiring direct manual intervention. By adding an IR to your HVAC technician toolbelt, you can find and repair potentially hazardous components.

2. A Digital Multimeter Provides Important Information About Electrical Components

A digital multimeter (DMM) is a diagnostic tool employed by technicians working with electrical components, including by students developing their electricity-related knowledge at HVAC college. The primary purpose of a DMM is to measure electrical values—namely amps (current), volts (voltage), and ohms (resistance). The advantage of a DMM is that it combines the efficacy of multiple single-task meters into one comprehensive device. In one single reading, the user can receive information that would otherwise require three to four separate machines and three to four separate readings.

3. Leak Detectors Can Help You Detect Leaks When You Become an HVAC Technician

Leaks are a problem that HVAC technicians are often called upon to address. Such leaks may be caused by abrasive substances, physical damage, equipment malfunction or a variety of other factors. What is just as important as the problem itself is the ability to detect it. If a gas leak, for example, goes undetected for a prolonged period, it might become a health and safety hazard.

A leak detector helps you see what is otherwise invisible. If a system is utilizing compressed air to generate energy, for example, and that system is leaking, it might result in decreased productivity because energy will be lost. After your HVAC technician training, you may find yourself called upon to help detect and fix leaks and in those cases a leak detector will prove invaluable.

4. A Vacuum Gauge Is a Useful Tool to Have for Refrigeration Systems

A vacuum gauge is an instrument that measures the pressure in a vacuum. They are one of the most important tools used in refrigeration. As an HVAC technician, a vacuum gauge allows you to test the pressure of liquids and gases in cooling systems, which is essential when working with different refrigerants. Vacuum gauges are also necessary when servicing or replacing a refrigeration system as they provide you with important information about the system.

Do you want to become an HVAC technician?

Check out the North American Trade Schools to find out about our programs!